Cement Industry Wear Parts

High-performance wear parts engineered for the demanding environments of the cement industry. Cast wear parts for the cement industry are essential components that endure significant abrasion, impact, and heat during the process of manufacturing cement. They are used in equipment like crushers, raw mills, kilns, coolers, finish mills, and conveyors to maintain operational efficiency and minimize downtime.

Reliable, Long-lasting Cement Wear Parts

With decades of metallurgical expertise and customer focus, we provide solutions that extend equipment life and reduce downtime.

At Falvey Steel, we’re dedicated to maximizing your productivity by supplying reliable, long-lasting cement wear parts. Falvey Steel can produce exact replacement castings for your current parts or redesign your parts for better wear life from engineering wear studies of your worn parts profiles. Falvey Steel owns thousands of existing drawings for cement plants all over the world.

We’ve significantly expanded our offerings through the acquisition of Columbia Steel’s technical assets and engineering drawings for their entire Cement wear parts product line. This means you can now confidently turn to Falvey Steel for replacements, including:

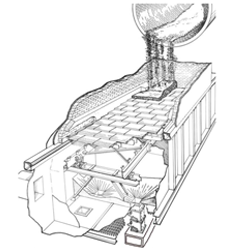

Quarry Crusher Parts

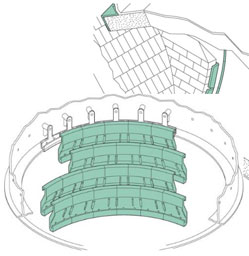

Kiln and Cooler Parts

Preheater Parts

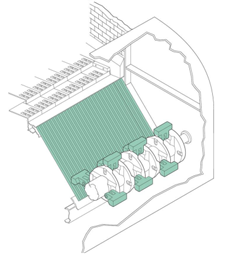

Clinker Breaker Parts

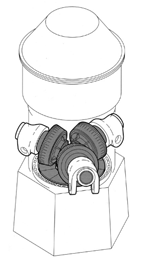

Roller Mill Parts

Finish Mill Parts

Conveyor Parts

Get In Touch With Us

Falvey Steel Castings – Cast wear parts in various materials to meet your application needs

| METAL | PROPERTIES | APPLICATIONS |

|---|---|---|

| Manganese Steels | Available in 14%, 18%, and 22%. High resistance to abrasion, material will work harden and have an ending higher hardness rating than that at the beginning. | Crusher hammers, breaker bars, impact bars, and liners. Feeder flights. Conveyor chains. Miscellaneous parts subject to high impact. |

| High Strength Alloy Steels | Higher hardness rating than manganese when cast. High hardness throughout. Excellent abrasion resistance | Crusher hammers and Crusher wear parts. Finish mill grates. Paddles and Conveyor chain. |

| High Temperature Stainless Steels | Various steel alloys for high temperature or corrosive resistance applications. | Wear parts located in preheater, kiln, and cooler applications. |

| Chromium Steels | High abrasion resistance, offered in chrome iron properties. | Clinker breaker hammers. Vertical roller mill tires, table liners and guide pins. |

| Ceramic Composite Steels | High abrasion resistance, offered in chrome iron properties. | Vertical roller mill tires and table liners. Hammermill parts. Impactor parts. |

| Carbon Steels | Ductility, weldability and heat-treated tensile strength levels up to 100 KSI — all common grades | Roll brackets and yoke assemblies. Crusher torch rings, locking nuts and toggle plates. Industrial parts |

Kiln & Cooler Parts

Clinker Breaker Parts

Roller Mill Parts